On Your Marks: How the London Assay Office Produces Hallmarking Punches Using Laser Technology

Have you ever wondered how hallmarking punches are produced? This article explains how the London Assay Office are using the latest laser technology to improve the accuracy of your hallmarking punch.

The traditional method of applying marks which make up the hallmark is with a punch. In recent years laser technology has brought about significant developments to Assay Offices and the hallmarking process. The manufacture of punches using laser technology is still in its infancy but the key steps in the method are:

3D Image Design

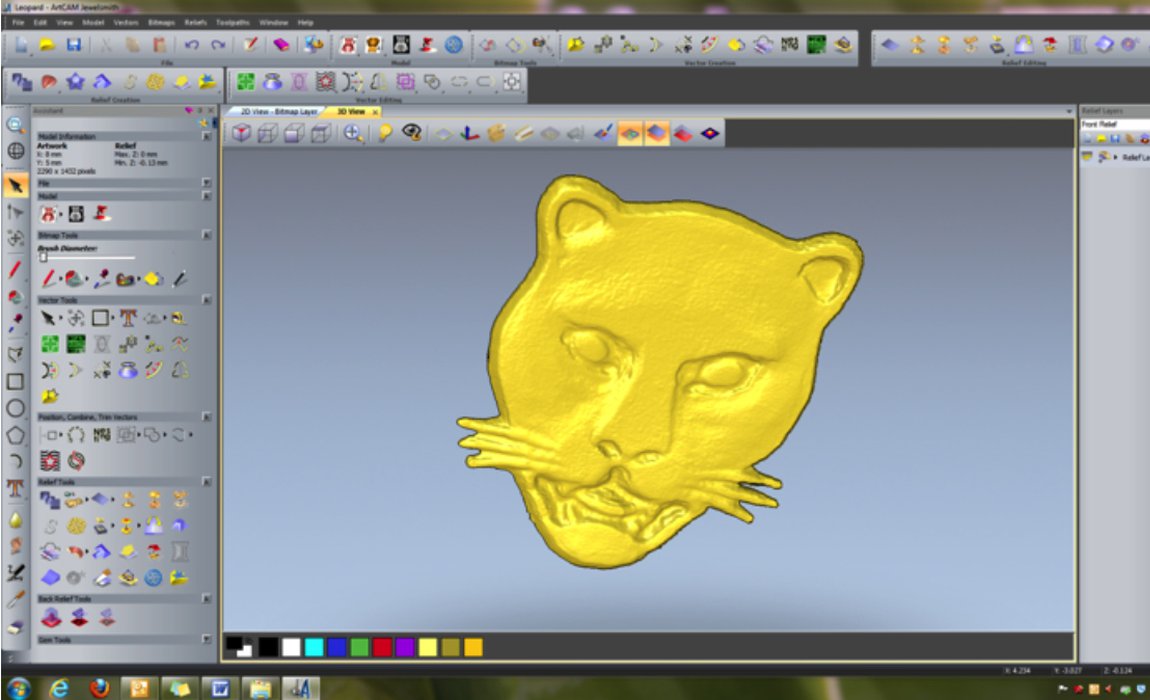

An image must be produced, and this can be done either by a 3D scan of a master copy of the mark to be applied, or by drawing the design in suitable 3D design software, such as Artcam or Type 3. A combination of the two is often used. A key challenge of the design is to get the level of detail right. For example, a detailed leopard’s head, like in Image 1 below, may be suitable for marking at 2mm or above, but at smaller sizes the detail merges and the final mark suffers.

The 3D program converts the image into a stereo lithography (STL) file, a format which can be read by the laser and contains the geometry of the image.

3D image of leopard’s head designed in Artcam software.

3D image of leopard’s head designed in Artcam software.

Laser Set-Up

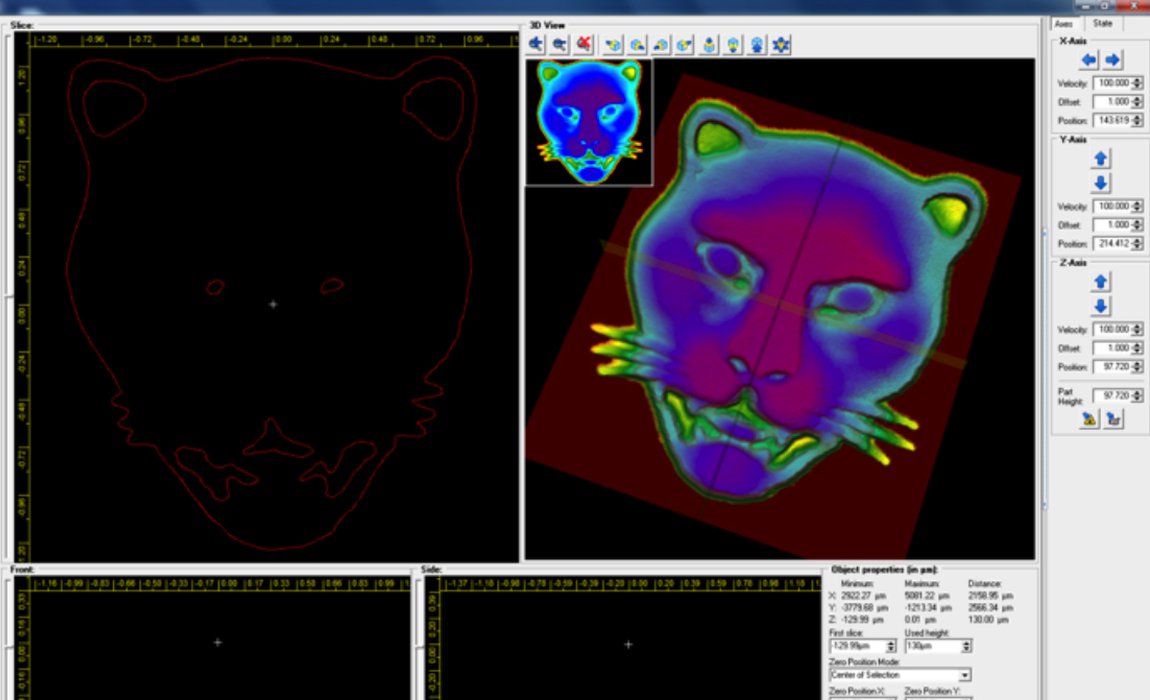

Once a suitable STL file has been produced, it is loaded into the laser which interprets the data and calculates the number of passes that should be applied. The calculation is based on previous calibrations on the material used. The best resolution for a smooth finish is often found to be around half the beam width per layer step.

View of layering to be cut on laser control software

View of layering to be cut on laser control software

Insertion of the Punch Blank

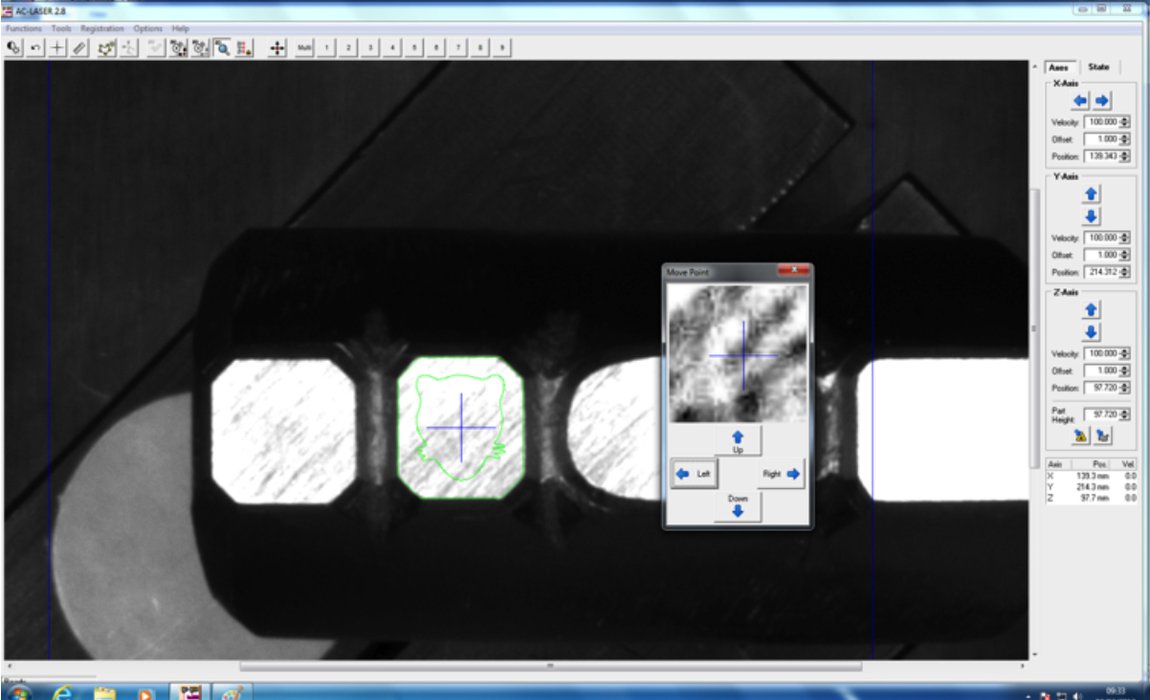

When ready to start engraving the punch, the size of the surface of the punch blank is chosen to be as near as possible to the size of the mark. This minimizes the amount of later finishing required. Before beginning, the surface of the punch blank needs to be polished to ensure it is clean of debris and grease. The material used in the punches is a water-hardened ‘W1 steel’.

Once in the laser machine, a visible light positioning laser is used to align the punch blank correctly as seen in Image 3. As with all parts of the process, accuracy is key.

Positioning laser used to locate image to be etched on punch.

Positioning laser used to locate image to be etched on punch.

Etching

This is the main part of the process and multiple stations on the laser allow several punches to be cut in sequence. This allows the laser to run consistently over long periods and with limited need for human monitoring. Laser etching takes a significant amount of time, especially with the material used for punches. For example, a two letter, 0.5mm high sponsor’s mark takes 57 minutes to cut over 1200 layers.

Finishing and Hardening

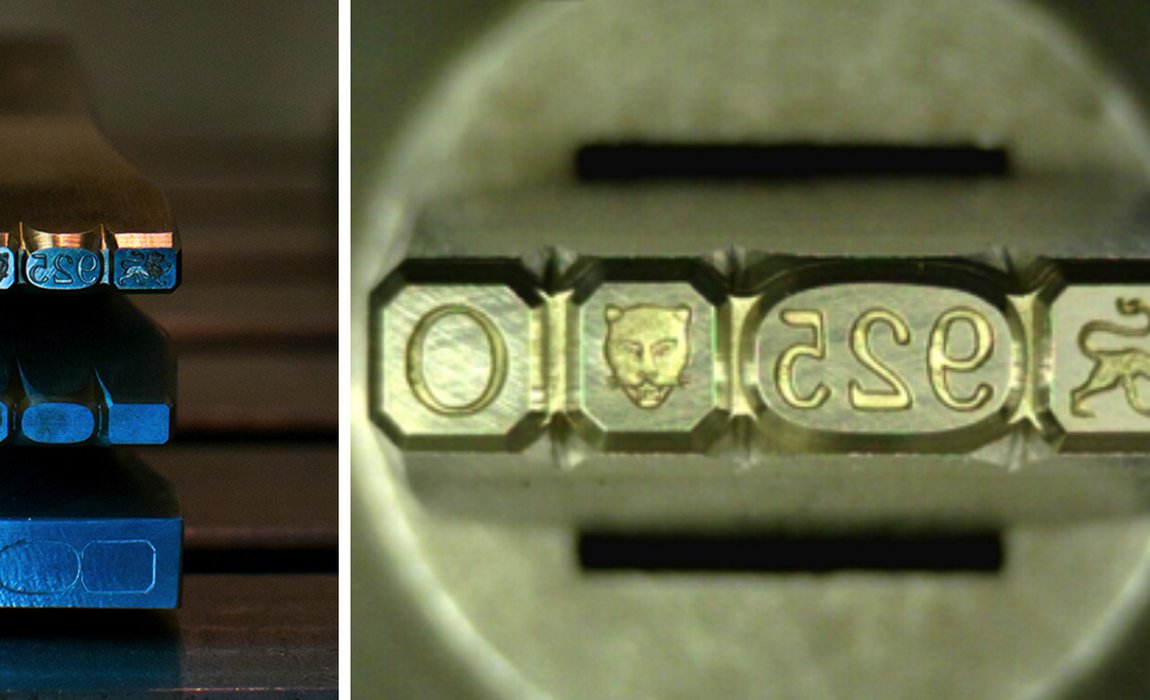

Once the laser etching is completed, the punch is hand finished and hardened. Finishing includes filing the ‘shoulders’ of the punch by hand up to the edge of the shields around the mark. This is done whilst the punch is in a softened state before being tempered and water quenched to harden the surface.

A visual check is also carried out to ensure the quality of the punch prior to it being approved for use.

Finished punch.

Finished punch.

Conclusion and further information

It has been found that a key benefit of using laser technology for punch making is that the resolution is significantly better than those produced using pantograph technology. This is especially true on punches with marks below 1mm shield size. This is because the width of a laser beam is much finer than the radius of the point on a mechanical cutter.

There are many reputable sources of information relating to the jewellery, silversmithing and allied industries. Whether you are trying to find information on technical skills, processes, materials, makers or inspiration some resources relating to hallmarking can be found below:

The Goldsmiths’ Company Library relates specifically to gold and silversmithing, jewellery, assaying and hallmarking, precious metals, and the City of London and its guilds. The Library includes 8,000+ books and 15,000+ images, magazines, periodicals and journals, technical guides, films, special research collections, design drawings produced during the early and mid-twentieth century by British or UK-based craftspeople and subject files on a wide range of industry related topics. The Library is also responsible for the Company’s archives, which date back to the 14th century.

Hallmarking related articles include:

- Industry Profile: Assay Office Technician

- On Your Marks…the development in Assay Office marking technology

Author: Dr Robert Organ, Deputy Warden of The Goldsmiths’ Company